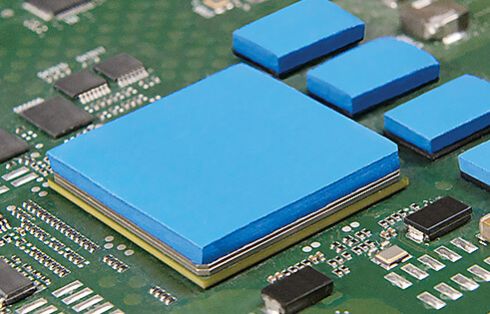

GAP PAD

GAP PAD HC 3.0

Features & Benefits

- Thermal conductivity: 3.0 W/m-K

- Highly conformable, low compression stress

- Fiberglass reinforced for shear and tear resistance

Properties

| Properties | Imperial Value | Metric Value | Test Method |

|---|---|---|---|

| Reinforcement Carrier | Fiberglass | Fiberglass | *** |

| Color | Blue | Blue | Visual |

| Inherent Surface Tack | 2 | 2 | *** |

| Density (Bulk Rubber) (g/cc) | 3.1 | 3.1 | ASTM D792 |

| Heat Capacity (J/g-K) | 1.0 | 1.0 | ASTM E1269 |

| Hardness (Bulk Rubber) (Shore 00) (1) | 15 | 15 | ASTM D2240 |

| Young's Modulus (psi) / (kPa) (2) | 16 | 110 | ASTM D575 |

| Typical Use Temp (°F) / (°C) | -76 to 392 | -60 to 200 | *** |

| Thickness (inch) / (mm) | 0.020 to 0.125 | 0.508 to 3.175 | ASTM D374 |

| Electrical | Imperial Value | Metric Value | Test Method |

|---|---|---|---|

| Dielectric Breakdown Voltage (Vac) | >5000 | >5000 | ASTM D149 |

| Dielectric Constant (1000 Hz) (3) | 6.5 | 6.5 | ASTM D150 |

| Volume Resistivity (Ohm-meter) | 10^10 | 10^10 | ASTM D257 |

| Flame Rating | V-O | V-O | U.L. 94 |

| Thermal | Imperial Value | Metric Value | Test Method |

|---|---|---|---|

| Thermal Conductivity (W/m-K) (3) | 3.0 | 3.0 | ASTM D5470 |

| Property | Value | Test Method |

|---|---|---|

| Shield / Copper Thickness (inches) | 1 |

| Deflection (% strain) | 10 | 20 | 30 |

|---|---|---|---|

| Thermal Impedance (ºC-in2/W) 0.040" | 0.57 | 0.49 | 0.44 |