Gap Filler

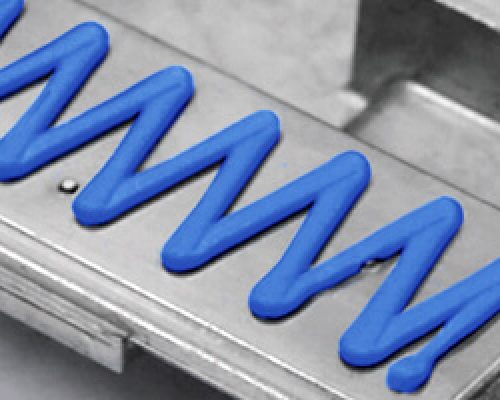

Gap Filler TGF 1450

Features & Benefits

- Thermal conductivity: 1.5 W/m-K

- Ultra-conforming with excellent wet-out for near zero interface stress

- No cure by-products

- Low density for weight sensitive application

- Excellent low and high temperature mechanical and chemical stability

- Shear thinning viscosity for ease of dispensing

Properties

| Properties | Imperial Value | Metric Value | Test Method |

|---|---|---|---|

| Color / Part A | Blue | Blue | Visual |

| Color / Part B | Light Blue | Light Blue | |

| Viscosity, High Shear (Pa-s)(1) | 30 | 30 | ASTM D5099 |

| Viscosity, Low Shear (Pa-s)(2) | 30 | 30 | ASTM D5099 |

| Density (g/cc) | 1.8 | 1.8 | ASTM D792 |

| Mix Ratio | 1:1 | 1:1 | |

| Shelf Life @ 25°C (months) | 6 | 6 | ASTM D792 |

| PROPERTY AS CURED | |||

|---|---|---|---|

| Cplor | Blue | >Blue | Visual |

| >Hardness (Shore 00)(2) | 40 | 40 | ASTM D2240 |

| >Heat Capacity (J/g-K) | 1.0 | 1.0 | ASTM D1269 |

| Continuous Use Temp (°F) / (°C) | -76 to 347 | -60 to 175 |

| ELECTRICAL AS CURED | |||

|---|---|---|---|

| Dielectric Strength (V/mil) | 275 | 275 | ASTM D149 |

| Dielectric Constant (1000 Hz) | 6.4 | 6.4 | ASTM D150 |

| Volume Resistivity (Ohm-meter) | 10^10 | 10^10 | ASTM D257 |

| Flame Rating | V-O | V-O | U.L. 947 |

| THERMAL AS CURED | |||||

|---|---|---|---|---|---|

| Thermal Conductivity (W/m-K) | 1.5 | 1.5 | ASTM D5470 |

| CURE SCHEDULE | |||||

|---|---|---|---|---|---|

| Pot Life @ 25°C (3) | 60 min | 60 min | ASTM D4473 | ||

| Cure @ 25°C(4) | 5 hours | 5 hours | ASTM D4473 | ||

| Cure @ 100°C (4) | 10 min | 30 min | ASTM D4473 |