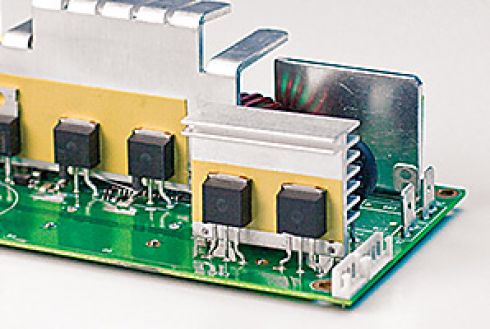

ADHESIVES

Bond-Ply LMS-HD

Features & Benefits

- TO-220 Thermal performances: 2.3°C/W, initial pressure only lamination

- Exceptional dielectric strength

- Very low interfacial resistance

- Continuous use of -60 to 180°C

- Eliminates mechanical fasteners

Properties

| Properties | Imperial Value | Metric Value | Test Method |

|---|---|---|---|

| Reinforcement Carrier | Fiberglass | Fiberglass | *** |

| Color | Yellow | Yellow | Visual |

| Typical Use Temp (°F) / (°C) | -76 to 356 | -60 to 180 | *** |

| Thickness (inch) / (mm) | 0.010, 0.018 | 0.254, 0.457 | ASTM D374 |

| Electrical | Value | Test Method |

|---|---|---|

| Flame Rating | V-O | U.L. 94 |

| Breakdown Voltage, Sheet (Vac) | 5000 | ASTM D149 |

| Breakdown Voltage, Laminated (Vac) | 4000 | ASTM D149 |

| Dielectric Constant (1000 Hz) | 5.0 | ASTM D150 |

| Volume Resistivity (Ohm-meter) | 10^11 | ASTM D257 |

| Thermal | Value | Test Method |

|---|---|---|

| Post-Cured Thermal Conductivity (W/m-K) (1) | 1.4 | ASTM D5470 |

| Lamination Pressure (75 psi) | Constant | IPO |

|---|---|---|

| TO-220 Thermal Performance (°C/W) | 2.1 | 2.3 |

| Adhesion | Imperial Value | Metric Value | Test Method |

|---|---|---|---|

| Lap Shear @ RT (psi) / (MPa) (2) | 200 | 1.4 | ASTM D1002 |